Lightweight structural concretes based on Laterlite Expanded Clay LWA are suitable for the realization of reinforced concrete loadbearing structures.

Performances

- Density ranging between 1400 kg/m3 and 2000 kg/m3

- Compressive strength varying from 15 to 60 MPa (150 to 600 kg/cm²).

- High mechanical performance.

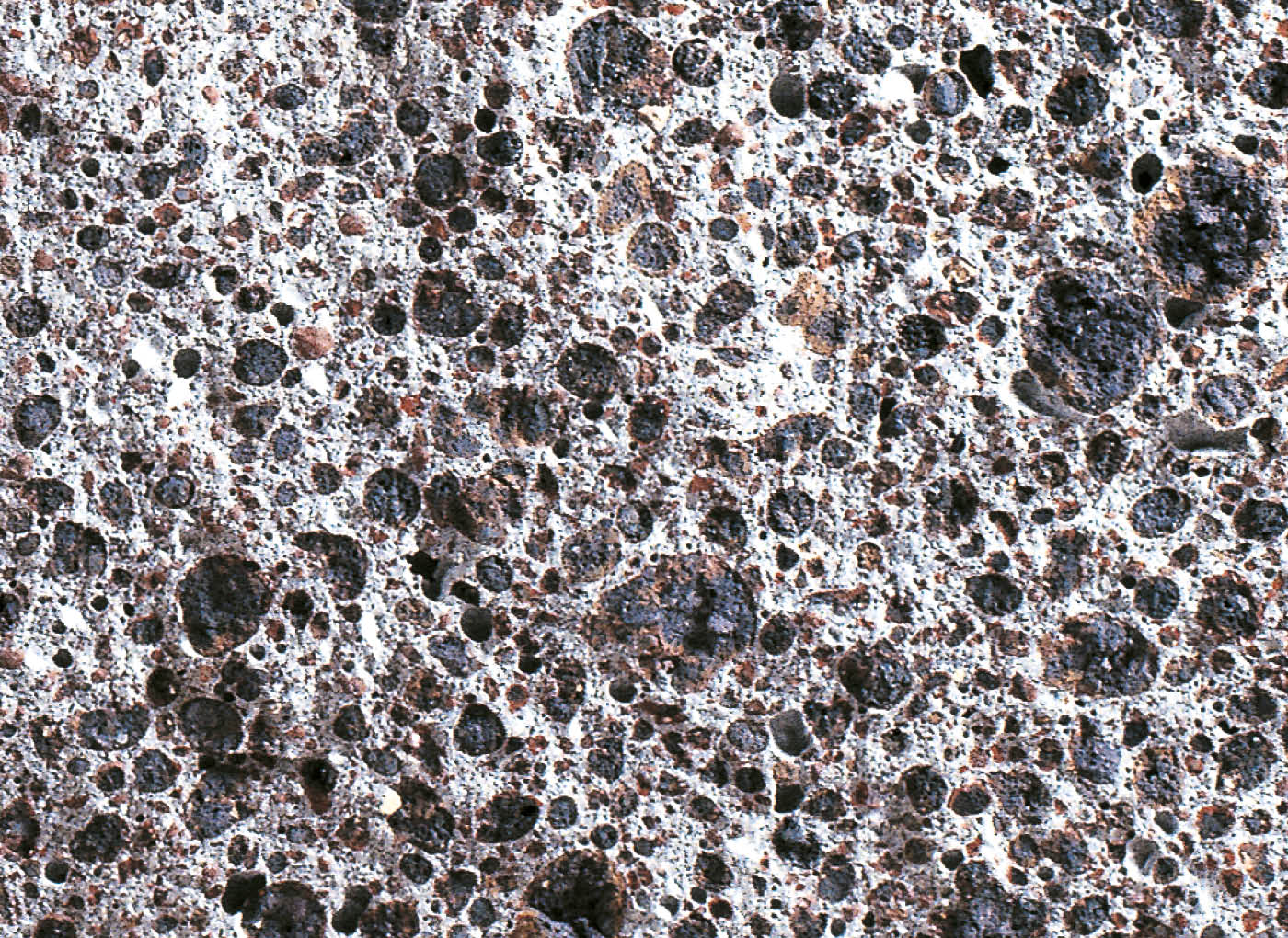

To produce lightweight aggregate concretes, depending on the required concrete properties, it is possible to use standard Laterlite or Laterlite Structural Expanded Clay, characterised by a less expanded porous inner core and a thicker and harder clinkerised outer shell, which achieves particularly high compressive strengths. The good strength characteristics of the aggregate are, in fact, essential to achieve the high mechanical performance of structural concrete.

Advantages

- Weight reduction: Laterlite Expanded Clay/Laterlite Structural can be used in lightweight structural concretes of density between 1,400 kg/m3 and 2,000 kg/m3, saving up to 1,000 kg (1 tonne) of dead load per m3 as compared to traditional concretes (2,400-2,500 kg/m3). On average, structures can be reduced in weight by 25% to 40%.

- Reduction of loads transmitted to the supporting soil

- Good mechanical performance: Laterlite Expanded Clay/Laterlite Structural can be used in lightweight structural concretes of high compressive strength from 15 to 60 MPa (150 – 600 kg/cm2). i.e., for all the same purposes as traditional concretes. The tensile strength, flexural strength, pullout strength, and dimensional stability (shrinkage and creep) of these concretes are comparable to those of traditional concretes in the same class.

- Structural calculation and statutory verification: Lightweight concretes based on Laterlite Expanded Clay can be formulated and designed to comply with international reference standards (EN 206, Eurocode 2, etc.)

- Easy to pour: Most lightweight structural concretes based on Laterlite Expanded Clay are pumpable (particularly those of density greater than 1650 kg/m3), This simplifies the site pouring process which is like that of an ordinary concrete. (Consult Technical Support)

- Better behaviour in the presence of fire: The insulating and refractory properties of Laterlite Expanded Clay used in lightweight structural concretes give a better performance than that of ordinary concretes in the same class.

- Good insulating characteristics: The lambda (λ -thermal conductivity) of lightweight structural concretes based on Laterlite Expanded Clay/Laterlite Structural is up to 4,5 times lower than that of an ordinary concrete, reducing thermal bridging through external facades and increasing the energy efficiency of buildings.

- More efficient transportation and simplified handling: thanks to the lower density of the concrete, particularly in precast components of large size.

APPLICATIONS

Renovation and reconstruction work in general

The use of lightweight structural concrete for reconstructing floor slabs, for adding floors to existing buildings, and all other types of strengthening works to structural concrete (columns, loadbearing walls, edge beams, floor slabs, staircases, balconies etc.) helps to avoid overloading the existing structure and foundations.

Complex architectural projects

When the weight of concrete elements is reduced, greater design freedom, leaner structures, and fewer structural constraints become possible.

Reduced thermal bridging in the building envelope

Thermal bridging caused by structural elements that pass through the external envelope (facades, roofs, foundations, etc.) is reduced by up to 4 or five times, reducing heat loss and the risk of building pathologies, and making it easier to comply with more restrictive regulations and certification protocols.

In structures where the self-weight is greater than the loads carried

In large-span bridges, precast Y-shaped roof beams, large precast panels, floor slabs with wide spans etc., the use of lightweight structural concrete enables structures of reduced cross-section to be created that require smaller amounts of concrete and reinforcement whilst also giving aesthetic and economic advantages.

Structures bearing on soils of low bearing capacity

The complexity and cost of foundations can be minimised by reducing their structural weight. This enables the same loads to be supported, enabling larger buildings to be constructed.

New construction and reconstruction work in seismic zones.

The extent of seismic action is proportional to the mass of the structural elements affected; the use of lightweight structural concrete reduces the seismic stresses acting on them by reducing the inertial masses of the structure.

Precast structures and elements

Precast lightweight structural concrete elements are easier to manoeuvre, more economical to transport, have a leaner cross-section, give better insulation, and have better fire resistance than precast elements made with ordinary concrete.

An “insulating” structural concrete has a mix design optimised for low thermal conductivity.

Producing a concrete that is both insulating and structural is possible thanks to the excellent thermal and mechanical properties of Laterlite expanded clay lightweight aggregates: the combination of its porous inner structure and its hard, clinkerised outer shell, in fact, offers a unique balance between thermal conductivity and mechanical strength.

Through special formulations, it is possible to reduce the thermal conductivity of the concrete by 3 to 4.5 times compared to a conventional structural concrete, while maintaining a high mechanical strength (25 to 35 MPa in compression).

Low thermal conductivity structural concretes based on Laterlite expanded clay lightweight aggregates are particularly useful for reducing thermal bridges caused by the structural elements of the building envelope, making it possible to comply with regulations without modifying the usual construction techniques by avoiding complex construction devices for breaking thermal bridges.

Its use is particularly useful at the junction between facade and slab in the case of thermal insulation on the inside or in double leaf walls, but also in balconies and other protruding cantilevered elements, in load-bearing masonry built-in reinforcements and in all concrete elements of perimeter walls, roofs, ground floors, etc.

The low conductivity structural concrete is also available bagged premixed under the name Latermix Beton, allowing the control of thermal bridges in projects of any scale.

Characteristics

- Lambda thermal conductivity between λ 0,4 and 0,6 W/mK (Lambda ordinary concrete λ = 1,9 W/mK)

- Compressive strength from 20 to 35 MPa (200 to 350 kg/cm2)

- Density of 1400 to 1600 kg/m3.

Concrete batching plants can also be used to mix very lightweight non-structural concretes for use as lightweight backfill and in levelling layers. For more information contact Technical Support.

To produce concrete for backfilling, screeds, levelling, embankments, falls and for any lightweight concrete layer supported by a load-bearing element (slab, deck, ground, etc.), non-structural lightweight aggregate concrete based on Laterlite Expanded Clay can be produced. Main types are:

- No fines concrete (pervious concrete), density between 450 and 800 kg/m3 and compressive strengths varying from 1 to 3 MPa.

- Plain, ordinary concrete, density between 1,000 and 1,400 kg/m3 and strengths between 3 and 20 MPa.

- ReoLaterlite type – superfluid – density 800-1000 kg/m3, compressive strength approx. 2.5 MPa.

Most of these concrete types are also available in bagged premixed version, see Ultra Lightweight Pervious Concretes and Lightweight Screeds.

Advantages

- Up to more than 75% reduction of dead loads applied on load-bearing structures.

- Thermal insulation.

- Durability and stability over time.

- 100% mineral non-combustible concrete.

FIELDS OF APPLICATION

- Reduction of overloads on load-bearing structures in renovation and new construction.

- Light fillings and embankments with high resistance/rigidity.

- Screeds, levelling, falls on slabs and roofs.

- Alignments and slopes on viaducts.

- Drainage (cavernous concrete).

Lightweight concretes containing Expanded Clay Laterlite can be manufactured:

- In concrete batching plants or in precast concrete plants.

- In bagged premixed version to be mixed on site with water only

Laterlite Expanded Clay structural concretes mixed in batching or precasting plants can be poured using a chute or a bucket as for conventional concrete, and some of them can be pumped. Pumped pouring requires the correct mix design to be defined (contact Laterlite Technical Support). The following processes can be used:

- SCC Technology (self-compacting concrete)

- Pre-soaking the expanded clay.

The different mix ratios are generally configured to meet the final design requirements and adjusted to include locally available aggregates.

For specific information and for the mix design of lightweight structural concretes, contact Laterlite Technical Support.

Lightweight concretes made from bagged premixed products based on Laterlite Expanded Clay aggregate are ideal for small and medium-sized construction sites or sites that are difficult to access.

The bag contains an optimised mixture of aggregates, cements and additives, the final mixing is made on site with the addition of water only. Pumping is possible with pneumatic batch pumps (screed conveyor type – see products TDS for relevant information). See Lightweight structural concretes, Ultra lightweight pervious concretes, and Lightweight screeds.