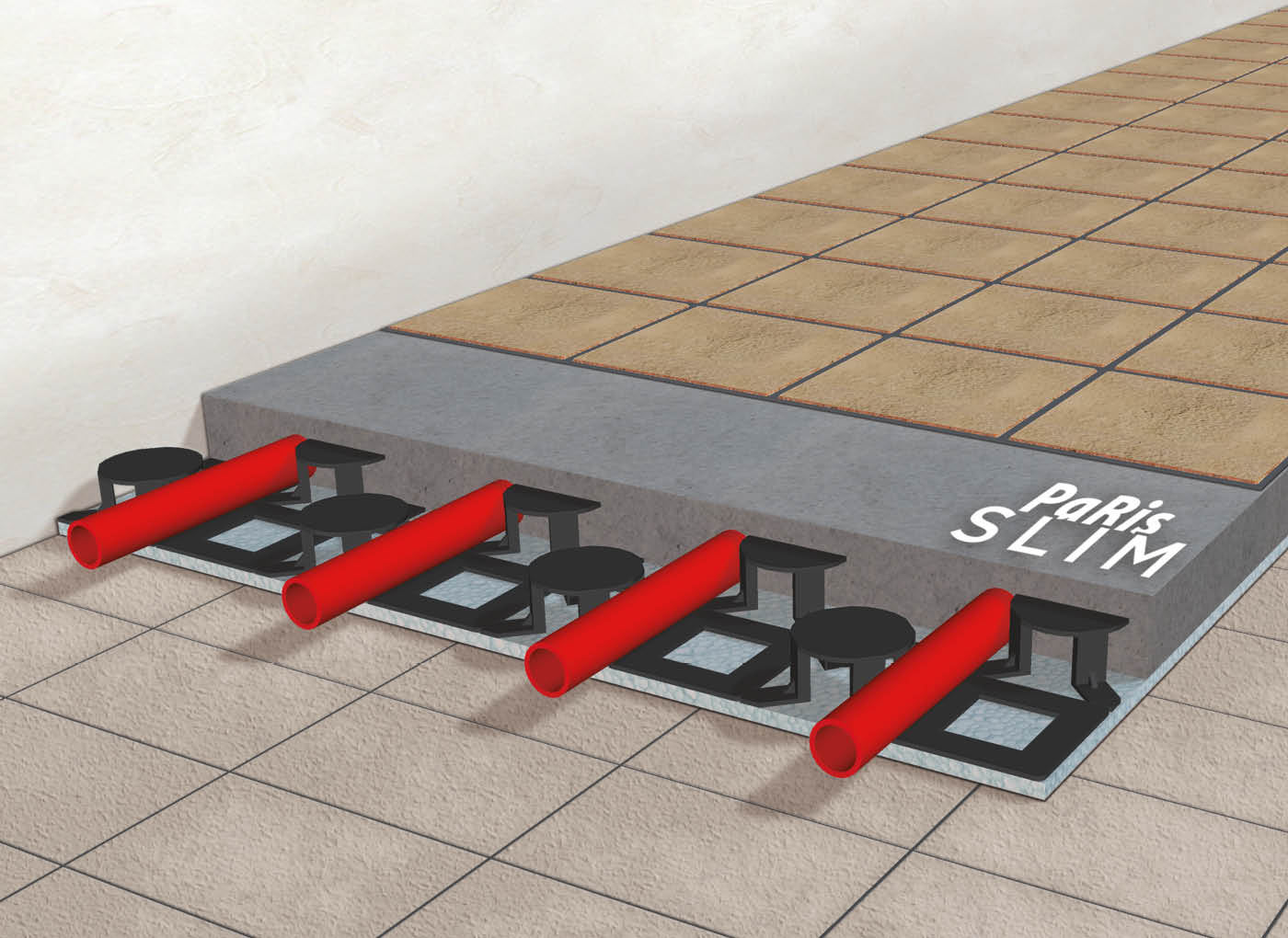

Low underfloor heating screed thickness

The special proprietary compound with high mechanical strength allow PaRis SLIM to be applied in reduced screed depth over the heating pipes and pipe-locating castles, starting from only 5 mm (variable thickness depending on the characteristics of the system, see technical data sheet).

PaRis SLIM is ideal for underfloor heating systems requiring low thickness and reduced weight, and therefore ideal for this type of system in renovation works.

Early commissioning of underfloor heating

Underfloor heating system start-up process can begin after only 4 days, thanks to Paris SLIM characteristics

Thermally conductive

Paris SLIM has a certified coefficient of thermal conductivity (lambda = 1,66 W/mK) that gives better heat transmission in heated floor systems, i.e. it reduces operating costs and improves comfort levels.

Grandes superficies sin juntas de retracción

PaRis SLIM es un mortero de retracción compensada que permite realizar superficies muy grandes sin juntas (hasta 200 m²).

Shrinkage compensated screed – Ideal for large surfaces

Paris SLIM extremely low shrinkage enables large areas to be laid without joints (up to 200 m2).

Smooth surface, suitable for laying any floor covering

The surface finish of PaRis SLIM is very smooth and its surface is suitable for the direct laying of any flooring.

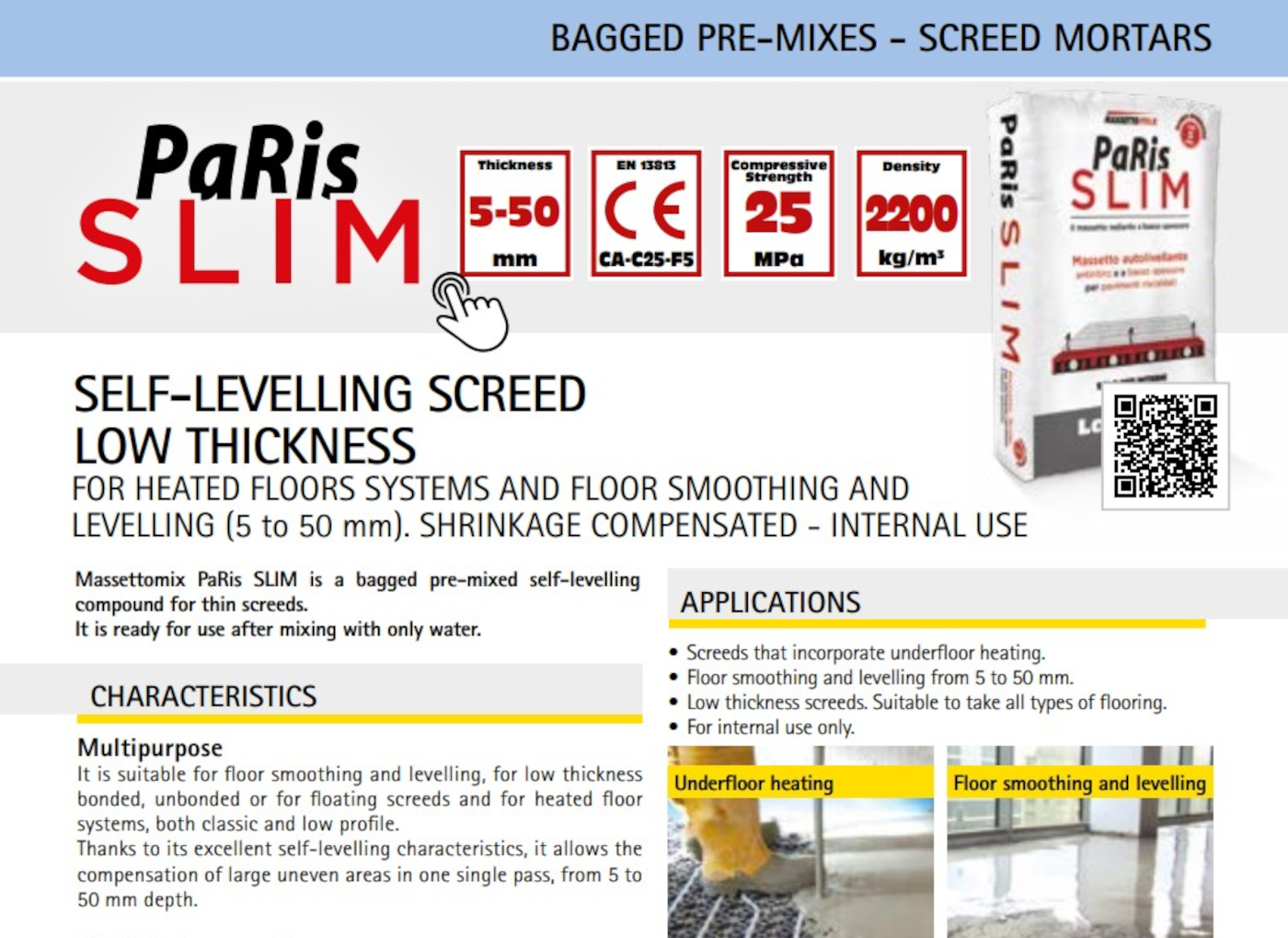

Multi-purpose screed

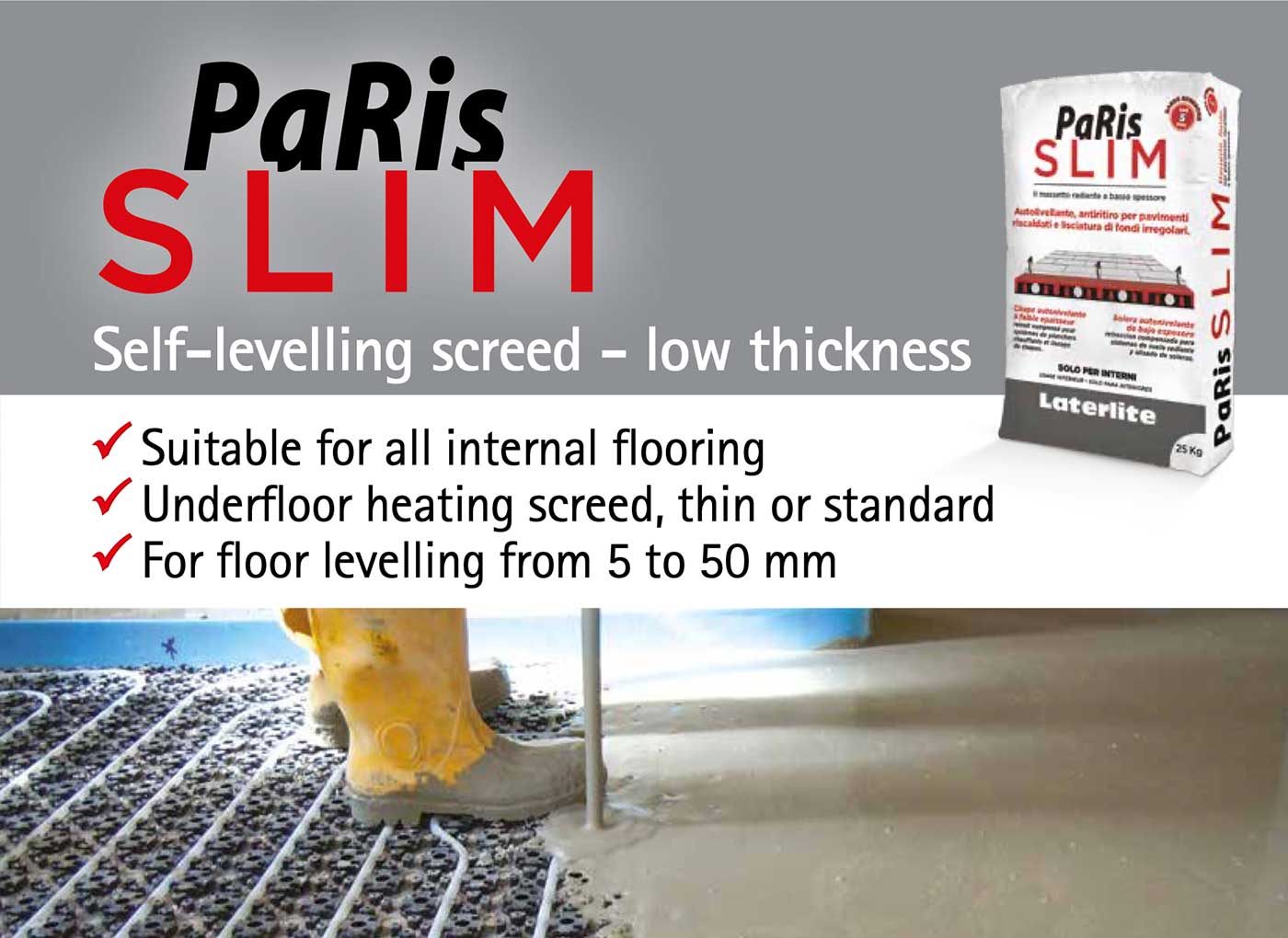

PaRis SLIM is suitable for screeds incorporating underfloor heating systems and for levelling, and smoothing new or existing substrates. PaRis SLIM can be applied as a bonded, unbonded or floating screed.

Levelling and smoothing of floors and substrates

PaRis SLIM has an exceptional flow and smoothing properties, allowing the levelling of uneven substrates and floors, in a single pass, in thicknesses from 5 to 50 mm.

Strong, stable, durable, and CE-marked screed

PaRis SLIM has high compressive strength (25 MPa), is CE-marked to denote conformity to EN 13813 (screed materials and floor screeds), is dimensionally stable and non-deformable, and retains its properties unaltered over time.

Please contact our technical support info@laterlite.com

Please refer to the product data sheet and documentation for complete information about application.

Apparent packed density (approx.) 1600 kg/m3

In-place density (approx.) 2200 kg/m3

Average compressive strength (EN 13813) N/mm2 (250 kg/cm2)

Thermal conductivity l 1,66 W/mK

Fire reaction: Euroclass A1fl (Incombustible)

Minimum application depth

Underfloor heating: screed depth over the heating pipes and pipe-locating castles

- Low depth underfloor heating systems (low thermal inertia):5/7 mm

- Conventional underfloor heating system with insulation board: 10 mm

Bonded screed-levelling compound: 5 mm

Unbonded screed: 20 cm

Floating screed: 30 cm

Maximum application depth: 50 mm

Laying of ceramic or stone finishes:

2 days (thickness 5 – 10 mm)

3 days (thickness 10 – 15 mm)

4 days (thickness 15 – 20 mm)

5 days (thickness 20 – 30 mm)

Laying of moisture sensitive finishes (2% RH)

4 days (thickness . 5 – 10 mm)

6 days (thickness 10 – 15 mm)

7 days (thickness 15 – 20 mm)

8 days (thickness . 20 – 30 mm)

CE marking EN 13813 CA C25 F5

Package: bags each of 25 kg on non-returnable wooden pallets, 60 bags/pallet – 1.500 kg/pallet.

Quantity required per 1 m2 of floor area 0,76 sacos/m2 per 10 mm depth

Storage life: 12 months from date of packaging.

For more complete, detailed, and updated information, please refer to the product data sheet and safety data sheet.