in junctions between the structural elements and the thermal enclosure of a building (the floor-facade connection, balconies, projecting elements, etc.) it is difficult to realise a complete thermal bridging solution and to prevent heat dispersion or the risk that building pathologies such as condensation, mould, etc.

The most sensitive points are mainly on façades, where elements with different thermal conductivity (pillars, lintels or beams embedded in the external vertical cladding) or interruptions and changes in the thickness of the insulation layers (junction between RC structure and infill walls, cantilevered projecting elements such as balconies and overhangs, etc.) are present.

Many national standards and regulations for the energy efficiency of buildings and passive houses require thermal bridging to be very carefully checked and measurable in terms of linear thermal transmittance (psi-value or ψ) and point transmittance (χ)

In this regard, Laterlite products offer various advantages:

THERMAL BRIDGES OF CONCRETE STRUCTURES – LOW CONDUCTIVITY STRUCTURAL CONCRETE

Structural LWAC concretes based on Laterlite Expanded Clay LWA have a low thermal conductivity (lambda value) that is up to 4.5 times lower than that of traditional concretes (e.g. Latermix Beton 1400: lambda 0.4 W/mK as opposed to 1.9 W/mK for ordinary concretes). When they are used for the load-bearing structure of a building they enable thermal bridging to be considerably reduced without any need to change the method of construction or to adopt complex thermal break systems. This is very advantageous in terms of simplifying construction, reducing construction costs, and for the structural performance of the building, particularly in seismic zones.

TAB

CONCRETE SLABS AND WALLS

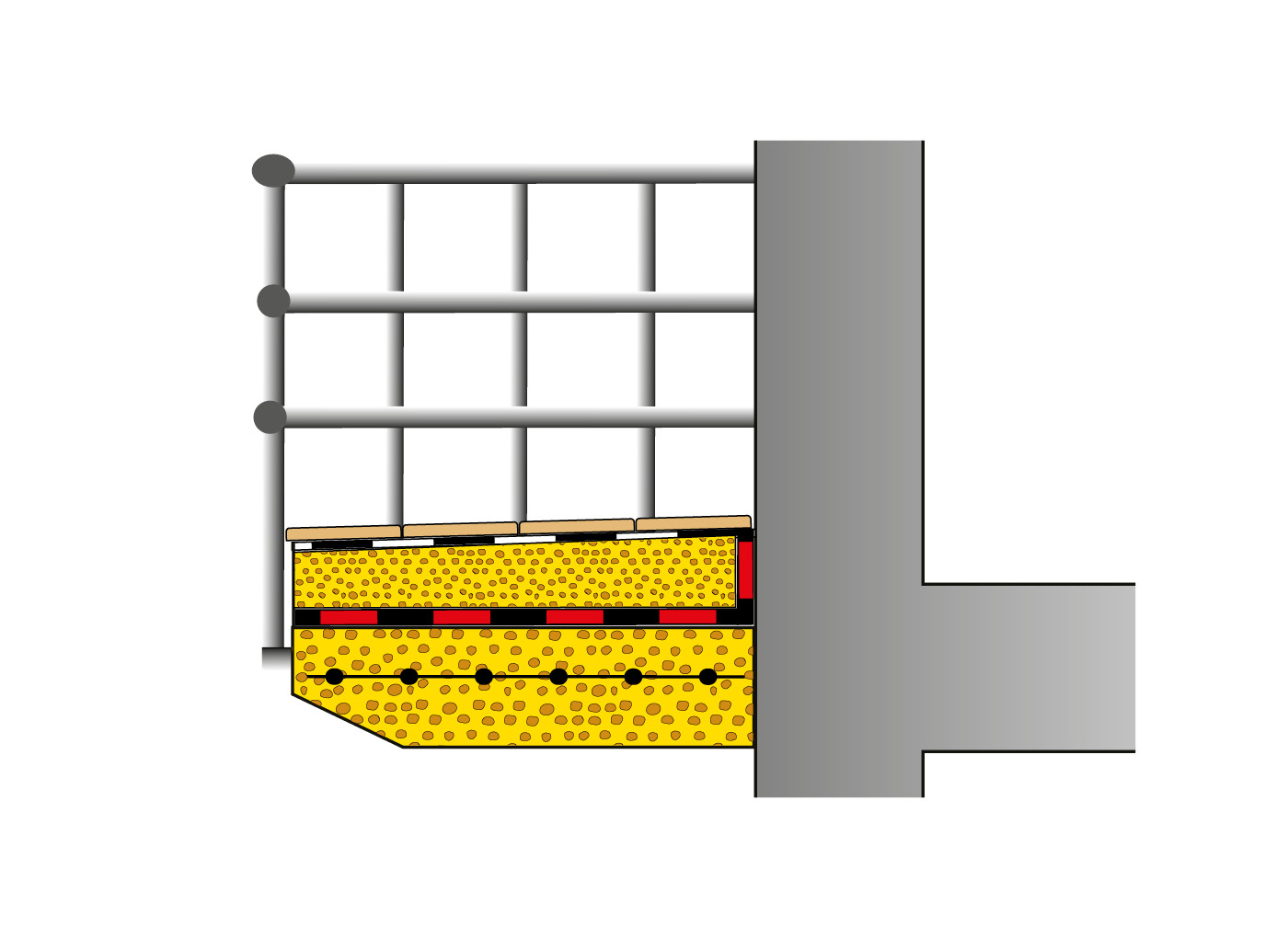

The wall/floor junction is a particularly weak point since the need for structural continuity means that the insulating layer is often interrupted or reduced at that junction, generating thermal bridges. The advantages of using Laterite structural LWAC for slabs and walls are particularly evident when insulation is applied to the internal face of walls or in wall cavities.

TAB

PROJECTING (CANTILEVERED) ELEMENTS

The control of thermal bridging at balconies, terraces, and all other projecting elements (canopies, gutters, eaves, etc) and in staircases built from concrete, can be greatly simplified by using low conductivity structural concretes based on expanded clay.

TAB

LOADBEARING MASONRY

The weakest points in load-bearing masonry walls occur where concrete stiffening elements have been incorporated and at particular geometrical configurations (e.g. corners). The use of lightweight structural concrete, particularly for insulating masonry with high thermal resistance, improves the thermal performance of the wall and prevents pathologies from developing.

TAB

OTHER ELEMENTS

Openings

It is often difficult to ensure the continuity or uniformity of the thermal insulation when constructing concrete elements (lintels, columns, door and window reveals, sills, etc.) that are close to openings. In these cases, the use of lightweight structural concrete enables thermal bridging to be greatly simplified and kept under control both at the design stage and during construction, and drastically reduces the risk of surface condensation when the dew point is reached, even if the insulation work has not been perfectly carried out.

Refurbishment

All of the advantages listed above also apply when a slab is refurbished to increase its strength, when an existing slab is replaced, if new elements (staircases, balconies, canopies, etc) have to pass through the thermal enclosure, or if strengthening elements made from concrete are required.

Screeds

Thermal bridging at slabs in new buildings or in refurbishment works can be reduced by using lightweight insulating products from the Latermix and Latermix Cem ranges for screeds and subfloors. These reduce lateral heat transfer and the sensation of cold at floor level.

CONTACT US