The sludge and slurry generated by livestock rearing, waste water purification, or biogas production are usually stored in special tanks, where chemical and physical “maturation” processes reduce their bacterial load and make them suitable for re-use (e.g. as agricultural fertiliser).

Sludge and slurry storage tanks floating covers made of Laterlite LCM Special Expanded Clay reduce the release of harmful gases into the atmosphere and help to prevent the development of unpleasant odours from sludge, which also enables compliance with local, national, and international standards.

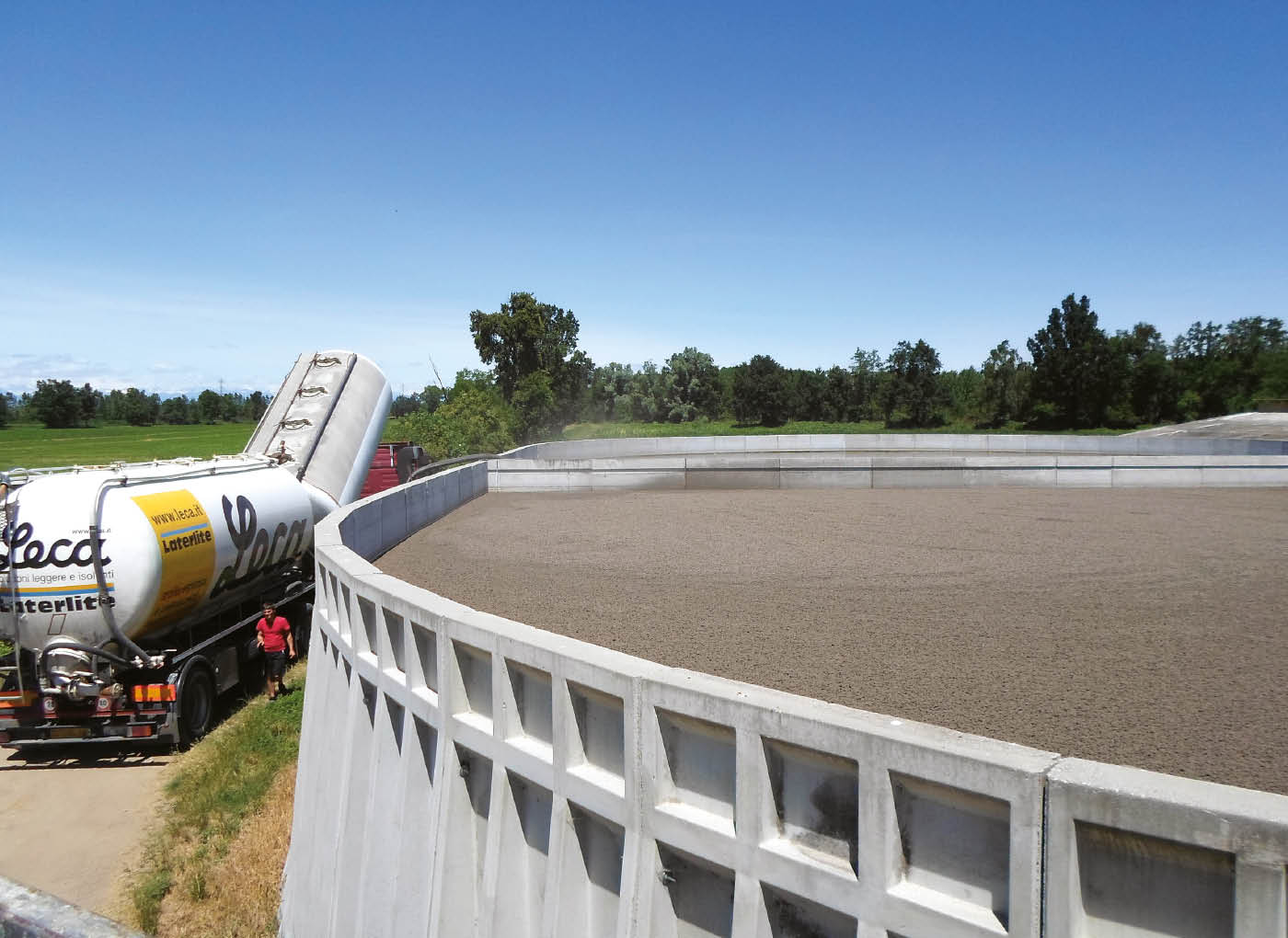

The process of constructing the cover consists of spreading a floating layer of Laterlite LCM Special approx. 10-15 cm thick that completely covers the surface of the effluent to form a continuous floating roof over the storage tank.

The layer of LCM expanded clay drastically reduces contact between the slurry and the atmosphere and reduces the release of gas. At the same time the granules encourage a bacterial biofilm to develop, which helps to degrade the pollutants and sets off a process of biofiltration.

CONTACT US